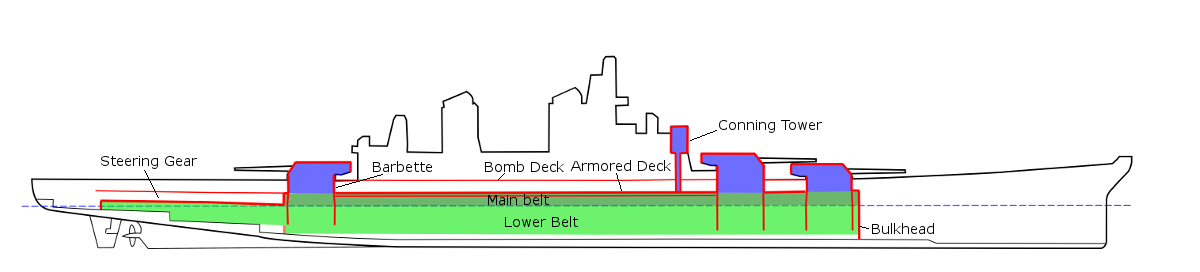

As battleship construction resumed in the late 1930s, designers were faced with an array of challenges that had only been on the drawing board when battleships were last built. These significantly changed the nature of the protection game, although they resembled the All-or-Nothing schemes of the last WWI-era battleships. Iowa's armor scheme was developed to meet these challenges, and examining it will show how they were met.

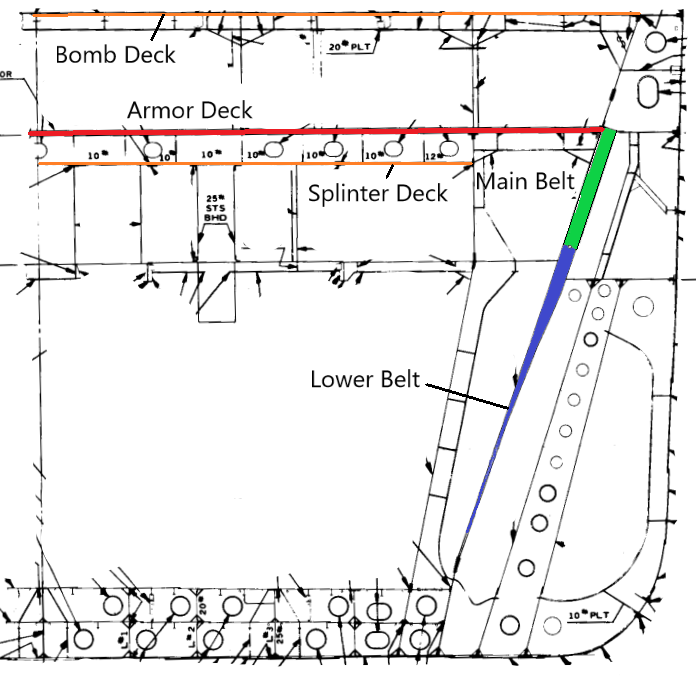

Iowa’s belt is 12.1” of US Class A armor1 on 30 lb STS,2 sloped at 19 degrees inboard.3 This slope makes it lighter than a vertical belt would be for the same immune zone,4 but requires the belt to be mounted inside the hull. This means that the damaged waterline of the ship is somewhat narrower than the undamaged waterline, compromising damaged stability. This tradeoff was forced by the treaty limits and the need to get through the Panama Canal, and the next class, the never-built Montanas, would have reverted to an external belt. To enhance the belt, the outer hull plating near the belt was 60 lb STS, an amount that should be sufficient to remove the AP caps from any shells, increasing the resistance of the belt by 30% or more and protecting the waterline from splinter damage.

A cross-section of Iowa at Frame 101

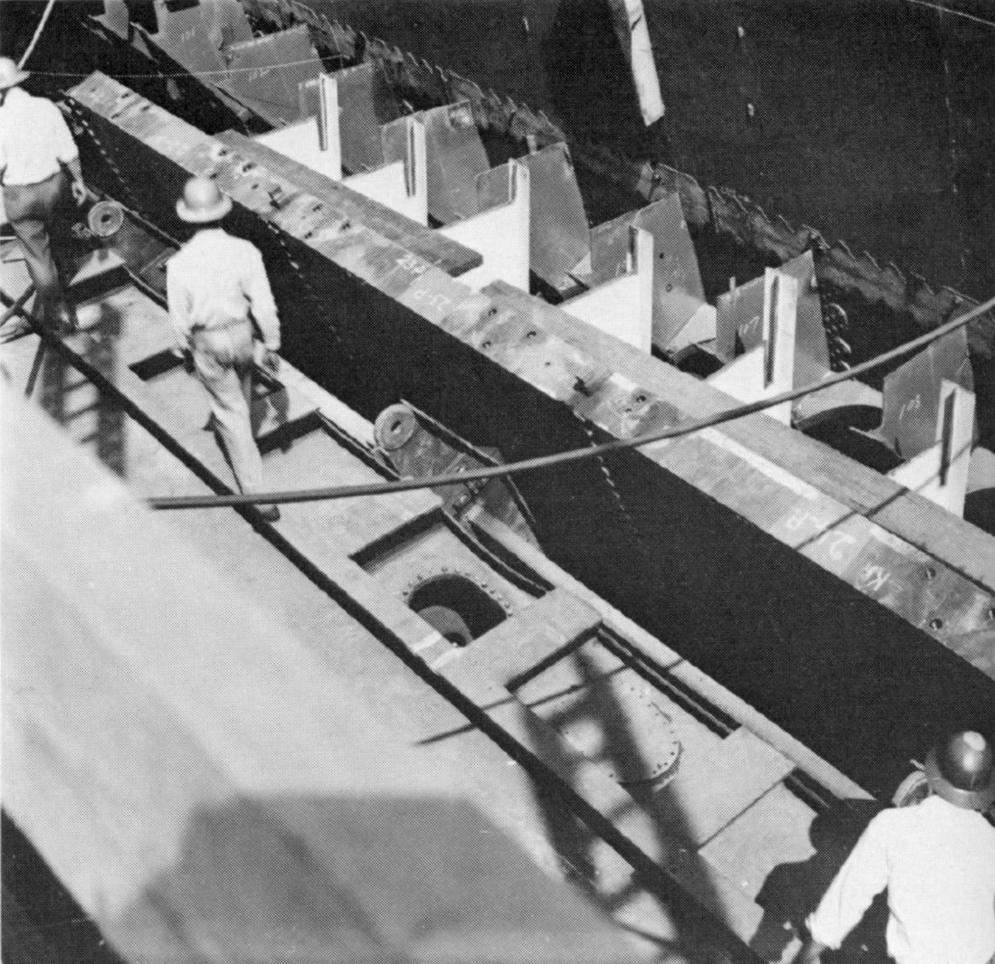

The lower strake of the Iowa’s armor is made of Class B armor and tapers from the full 12.1" down to 1.625” as it runs almost to the top of the double bottom. This was intended to counter underwater shell hits, which had become an increasing concern as battle ranges rose. Steeply-falling shells are capable of reaching deeper down the side of the ship before being brought to a stop by water resistance. In practice, very few hits of this type occurred on US warships, despite the Japanese optimizing their shells for this kind of hit. The lower bulkhead strake also forms the third bulkhead of the torpedo defense system. The transverse armored bulkheads that bound the forward and aft ends of the citadel taper from 11.3” to 8.5” on Iowa and New Jersey. These bulkheads were a known weak point in the design, and when the treaties lapsed at the start of WWII, the USN wanted to correct it. The armor for the first two ships had already been ordered, and replacing it would have imposed an unacceptable delay. On Missouri and Wisconsin, these bulkheads were increased to 14.5".

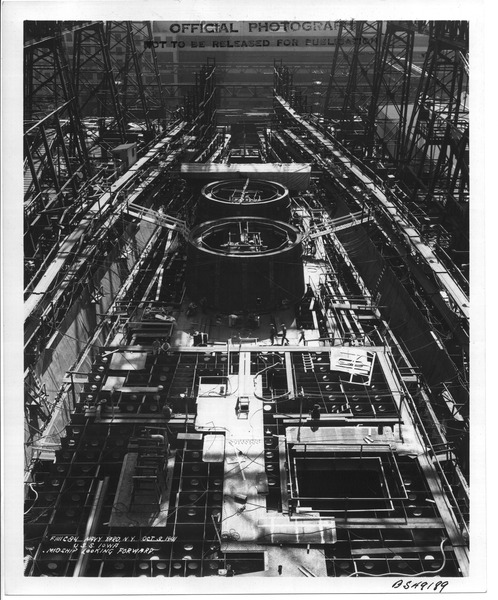

Iowa under construction in October of 1941. The barbettes are clearly visible.

The biggest new threat designers had to confront was the armor-piercing bomb. While pre-war predictions about the effectiveness of level bombing turned out to be grossly wrong, dive bombing was an important means of attacking ships. This actually made the task of protecting the deck less important, as the terminal velocity of an AP bomb was about 300 m/s, as opposed to the 150 m/s limits of a dive bomber.5

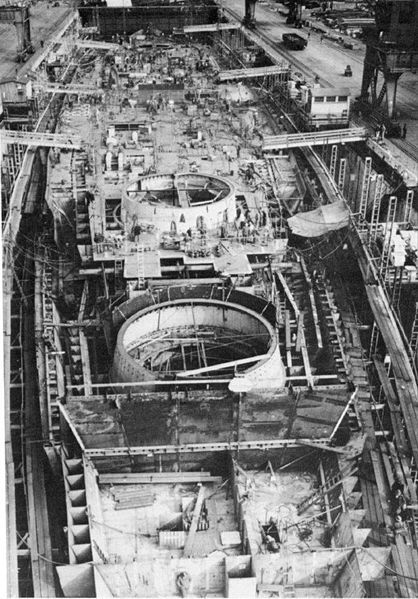

USS Kentucky under construction.6 The armor deck is being put into place around Turret II.

Iowa's deck protection is in three main layers. The main deck7 is 60 lb STS, and is called the bomb deck. The idea is to explode light-case HE bombs high in the ship, and start fuse action in AP bombs, hopefully detonating them before they reach the main armored deck.8 The 2nd deck is the main armor deck, 4.75” of Class B armor on 50 lb STS, intended to keep out shells and bombs. Directly below it is an mesh of empty compartments two or three feet deep, with a splinter deck of 25 lb STS closing them off below to catch any fragments knocked off the main armor deck.9

The lower belt as installed on Kentucky

The whole system was very similar to that of the South Dakota, with an immune zone of 20,400 to 26,700 yards against the 2700 lb shell from a 16”/45 gun and a zone of 17,600 to 31,200 yards against the same gun with a 2,240 lb shell. Against her own 16"/50 gun, these values are 23,600-27,400 yards and 21,700-32,100 yards respectively. Note that the outer edges of the immune zones are slightly greater for the 16"/50 guns, due to the shallower angle of fall. Reduced charges were proposed to solve this, but never fielded.

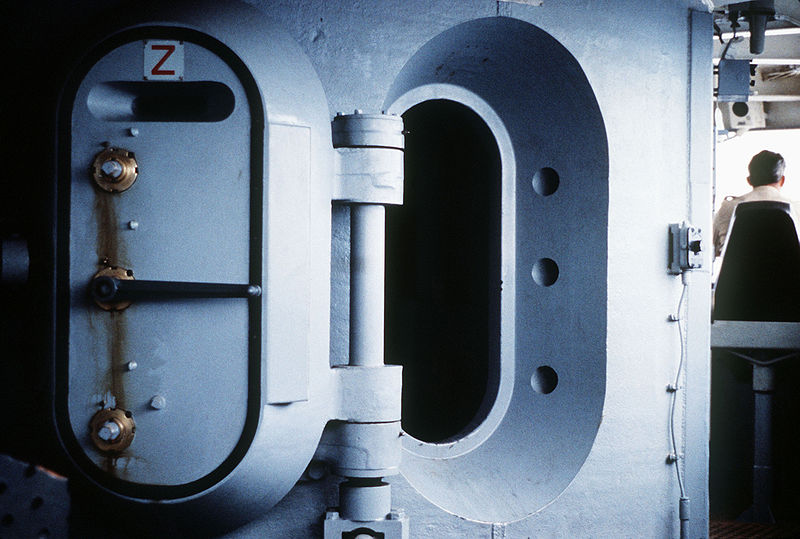

The conning tower door on New Jersey

The barbettes are 17.3” to 11.6” of Class A above the armored deck, with the thinner armor used when the barbette structure is screened by other parts of the ship. Below the armored deck, the barbettes are 3". The sides of the conning tower, essentially an armored vault for the admiral, captain, and gunnery officer, are 17.3" of Class B. The door alone weights over 2 tons.10 The turret faceplates are 17.0” of Class B on a 2.7” backing. The conning tower and turrets all have 7.25” roof plates. The rest of the turret armor is Class A, with 12” back plates and 9.5” sides.

Inside Iowa's steering gear room

Aft, the armored deck drops down to the 3rd deck and runs aft to protect the steering gear and the connections to said gear. This is 6.2" of Class B over the gear itself, and 5.6" over the steering gear leads. The communications tube to the conning tower is 16" across inside, and 16" thick. The secondary battery has 2.5" of STS, and the directors and director tubes vary between 1.5" and 2.5" of STS.

Battleship armor is a fantastically complicated subject, and I haven't been able to cover everything here.11 It's not as easy to sum up as gunpower, but understanding the battleship's defining feature gives a much better view into the conditions the ships were expected to face.

1 There's an interesting story behind this armor. British and German armor manufacturers achieved about a 25% improvement over the early-20s armor for their battleships, and the US didn't. This was not due to inferior US metallurgy, but due to a quirk of US armor testing. The US standard was centered around making sure that the shell didn't penetrate the plate intact and in condition to detonate, so as US shells got stronger, the hardened layer got thicker. This meant that the shell was more likely to penetrate in a damaged state, instead of being kept out. Nobody else tested this way (or made shells as strong) so they didn't have the same problem. ⇑

2 Special-treatment steel, essentially a homogeneous armor steel. Distinguished from Class B armor because it was provided by the Bureau of Construction & Repair instead of the Bureau of Ordnance. Usually thin, and used extensively above the waterline for structural purposes. ⇑

3 Bottom-in, the opposite of the way armor is laid out in a tank. ⇑

4 As pointed out earlier, the advantage of sloped armor is explained incorrectly in most literature. The sloped belt was no lighter than a 12.8" vertical belt would have been, although it would have been about 3% more effective at a 0° angle of fall due to deflection effects. However, this is not the main effect. As the angle of fall increases, the belt grows apparently thicker more quickly than a vertical belt would. At 40°, the shell is going to end up passing through 40% more metal on the sloped belt than on a 12.8" vertical belt. There will be some different in deflection, but not that much. ⇑

5 The German development of the guided bomb during the war removed this limitation, and such weapons were one of the most important factors in the final demise of the battleship. ⇑

6 Kentucky was a sister to Iowa, cancelled while under construction. ⇑

7 Which in this case is the deck on top of the hull with all of the wood on it. ⇑

8 This provides protection to a great deal of living space and workshops on the 2nd deck. Interestingly, this can be thought of as a return to the old armor schemes where sections of the ship were armored against light weapons. ⇑

9 This arrangement is somewhat compromised compared to a single heavy deck. To a first approximation, the main deck will be equal to 4.75" plus 0.7*1.25" or 5.625". The other plates will contribute about half their thickness to the total equivalent horizontal protection. ⇑

10 I always enjoyed pointing out to guests that this was probably more than their car weighed. ⇑

11 Much like the battleship designer, my task is to cover the important things and leave the rest bare. ⇑

Comments

If you have to be aboard a battleship during a firefight, where's the safest place to be?

Somewhere in the citadel, preferably near a way to get out. I'd say plotting room or sick bay.

You forgot to explain what STS stands for (and what it is). It's Special Treatment Steel, a high-percentage nickel steel that can support high loads and thus can be used as structural steel, unlike traditional armor plate.

I also found a link that seems to disagree with your first footnote:

"Testing by the U.S. Navy in 1921 of thick STS and face-hardened plates showed that the face-hardened armor only had an advantage when the damage that it caused the projectile was above a certain level (shatter of uncapped projectiles was always well above this level); if not, the hard, brittle face either did nothing to help or, in many cases, actually made the armor inferior to its unhardened form. As projectiles improved, the conditions where face hardening was the preferred solution became more and more limited. In fact, the U.S. Navy retained homogeneous armor for its heaviest turret faces during World War II when they discovered that it was better than any face-hardened armor against their own virtually indestructible armor-piercing projectiles when hit nearly square-on, as would be the case for a turret pointed directly at an enemy warship (face hardening was retained for thinner cruiser turret faces because the hard face caused less of a problem in these lower thicknesses and because uncapped projectiles were more likely to be used against the ship)."

Thanks for catching me not specifying STS. Fixed.

Traditional plate was often worked into hull structure. STS is distinguished from Class B armor because it was supplied by the Bureau of Construction and Repair instead of the Bureau of Ordnance. It was usually thinner, but according to Okun, that was the main difference.

Not really. The sweet spot for face-hardened armor appears to be 30-55 deg, based on a section just after the one you posted. This is valid for most of the vertical armor, while the turret faceplate is sloped back at about 45 deg, so it's almost always going to be hit at low obliquity. The source for the stuff on US Class A is on the same page.

When we talk about armor being sufficient to protect against a gun of some size...certainly for one hit, that makes sense. But how much long term ablation occurs?

For example, is there any (reasonably achievable before I shoot my CruRon dry) number of 8'' shells that would suffice to break through the Iowa's citadel due to accrued damage on plates that stop earlier hits? Or am I stuck just hoping to hit a single golden BB on the steering gear?

This used to be a relatively big concern. Early plates had a really bad tendency to fracture on impact, and there was some concern about follow-on hits in the same area. As battle ranges got longer and armor plates got better, not so much.

In terms of your actual question, I don't think so. They'd be able to mission-kill her (see Hiei and SoDak at Guadalcanal), but given what I know of cruiser-caliber hits on battleship main armor, I doubt they'd be likely to do very much. They tend to just kind of bounce. I don't think they ever repaired the 14" dent on SoDak's barbette.

BTW, r/WarshipPorn (a great subreddit) just posted this:

https://i.redd.it/4j8o3vkvgf901.jpg

Claimed to be (in comments) a turret face penetrated by a 16'' gun, though I'm not clear when or in what battle (or possibly seized after the war and done in testing?)

That’s a section of faceplate originally intended for Shinano. The hole was made by a 16" gun in postwar testing. See here for more details.

Can you describe the wooden decking over the steel bomb deck?

There's not a lot to say. It's an inch or so of wood (originally teak, mostly replaced with fir in the 80s) that was, so far as I know, never considered to have any ballistic effect whatsoever. Very good at keeping things cool down below, though, and not very slippery when wet.

I think WoW has answered the question on immunity zones regarding belts and why those immunity zones start at ~20,000m or so!

In most circumstances a battleships are running a zig-zag course or moving away or closing with an opposing vessel. Provided the belt is angled to 30 degrees or more most battleships will stop an opposing shell down to about 10,000m or so.

I don't think World of Warships has much to teach us on why ships were built the way they were, because ships in that game are not fought anything like ships in real life. (Or so I'm given to understand, anyway. I don't play it because Rule the Waves exists.) The problem with zig-zagging, for instance, is that until very late in the battleship's lifetime, that would have screwed up your fire control. Oh, and closing with the enemy often means running into torpedo range, which in RTW is terrifying because you want to keep your ships around for the next fight. Not to mention that you almost always fought battleships as a unit, which makes radical maneuvering basically impossible. That said, yes, oblique angles did make armor more resistant, as seen on cruisers, where they analyzed IZs with a 60 deg angle of engagement.