As a follow-up to my previous post with picture of Iowa's boiler room, I've put together a set of images from the engine room. I'm not going to spend a lot of time reviewing the actual mechanics of the ship's propulsion system, as I've discussed them at length elsewhere.

You step off Broadway, and into a tiny atrium, then go down one of the longest and steepest ladders in the ship. It's tricky even for me, and I'm pretty sure-footed around ships.

The ladder down to Engine 2. The yellow-and-black striped box is for lubricating oil.1

The most obvious thing is the reduction gearing, which steps the fast-rotating turbines down to the speed needed for the propellers.

The top of the gearbox in Engine 22

The reduction gearbox. Note the crew signatures from the decommissioning crew.

The high (left) and low pressure turbines, with the crossover pipe connecting them

Behind the turbines is the throttle board that controls the amount of steam let into the turbines. Conditions in the engine room were harsh, with temperatures often exceeding 120°F. The machinist's mates who ran the turbines drank lots of water and often failed to wear shirts.

The throttle board. The red wheel lets steam into the reversing turbine, while the green wheel controls the ahead turbine. They should not be opened at the same time.

The throttle valve which controls how much steam is let into the turbine

To back up the instruments, the man at the throttle board had a mirror which let him see the shaft as it left the gearbox (a closer view, below).

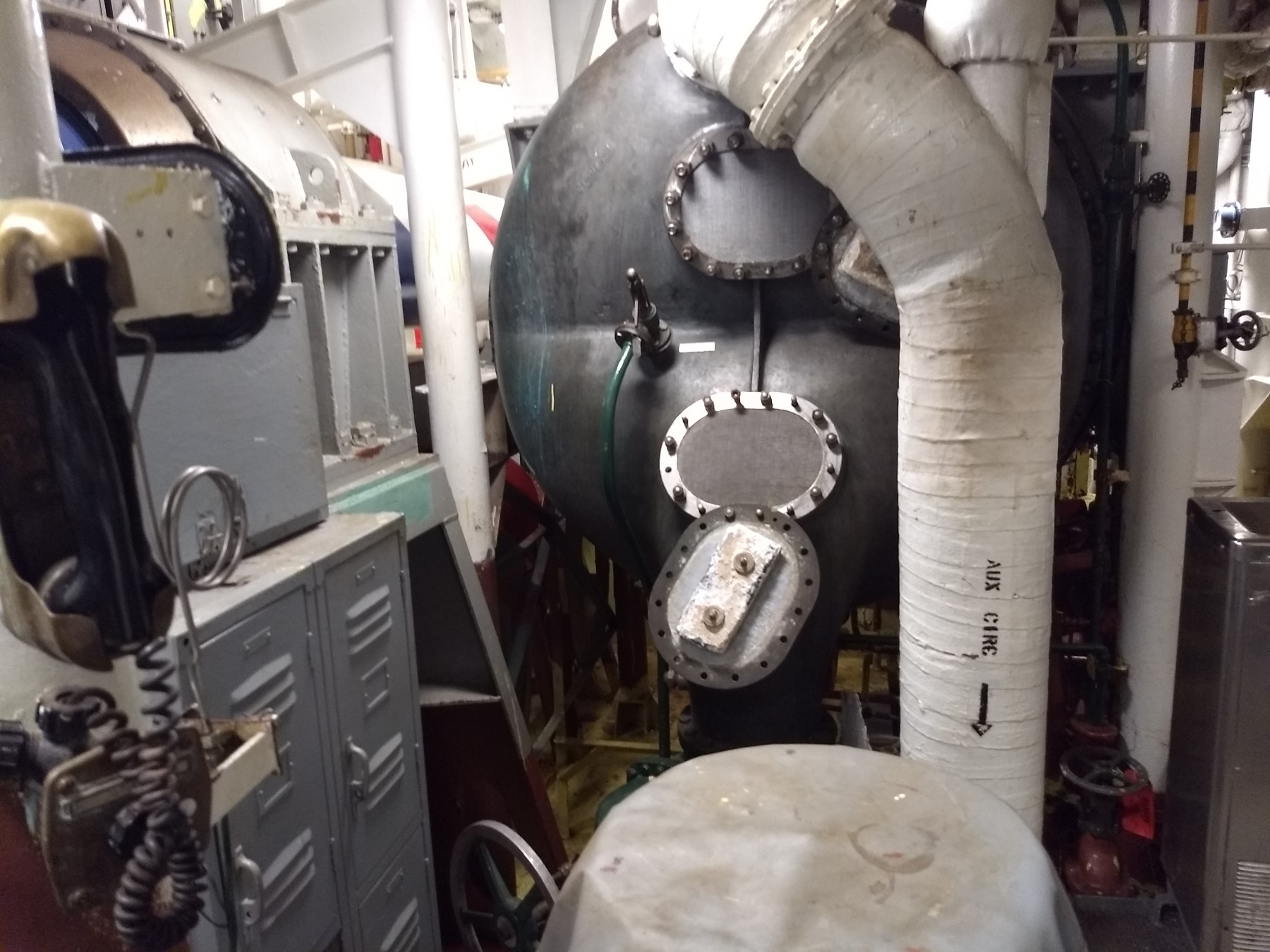

The condenser is on the lower level of the engine room, incorporated into the low-pressure turbine casing. It turns exhaust steam into water by passing seawater through a series of tubes to cool it.

The seawater intake for the condenser. At high speed, the motion of the ship rams water in, but at low speeds, a pump, such as the "Bilge Dragon" in the center of the shot is needed.

The condenser, showing the green piping for the seawater

On the other side of the engine room from the turbines are some of the ship's auxiliaries, most notably two of the 1,250 kW Ship Service Turbogenerators (SSTGs).

The turbine end of one of the SSTGs

The generator end of an SSTG. Note the painting on the far end of the SSTG.

Degaussing coils, intended to protect the ship against magnetic mines

The main switchboards in Engine 2

The condenser for one of the SSTGs, down below the generator unit. The access doors are open, and a zinc anode to prevent galvanic corrosion is visible on it.

The engine rooms turn the steam generated in the boiler room into both motion and electrical power. It's one of the largest spaces in the ship, and incredibly cool to see. If you want to visit it, Iowa offers the Full Steam Ahead tour, and I'd encourage you to take it.

Comments

These are some awesome pictures.

Is that story of the destroyer William D. Porter almost torpedoing the Iowa really true? Last night on a pilot's forum I read a rather amusing (if one can view it that way in retrospect...) account of the Porter launching a torpedo at the Iowa on 14 November 1943 as President Roosevelt was being transported to meet Churchill. Disaster was narrowly avoided apparently.

The account bordered on being fantastic and I thought I would check in here to see if it were true.

Yes, it is.

(That said, most accounts you find include a lot of details that didn't actually happen.)

Two thoughts:

There's lots of tags still aboard. In the aft fire control room, there's tagouts on the circuits for Turret II. And yes, there's a lot of crew art, most of it quite good. Probably has to do with having a crew five times the size of a destroyer.

Yes, of course there's still Red Tags hanging on certain circuits, especially on the Switchboards as they are, with the exception of the SSTG's, fully functional......they are live, on line and doing exactly what they did when the ship was active, as is the whole Electrical Distribution System, from the 4(out of 10) Shore Power Connections all the way down to the fluorescent lighting fixtures.

As refitted in the 80's all 4 IOWA's were fitted out with 8 shore power receptacles, this was modified during IOWA's first yard period at Norfolk Naval Shipyard(NNSY) where our Commissioning Electrical Officer(don't call me ELECO) Lt.(LDO) Anthony "Tony" Battaglia convinced NAVSEA that we needed two "spare" receptacles because every time the GM's lit off one of the Turret training motors itd trip us off of shore power.....each cable carried 400 amps 4x8=3200amps....4x10=4000amps....we never lost the load again do to overcurrent. The Switchboards are broken up into three sections, you have the upper level, the lower level and the Control Benchboard. the Control Benchboard is the section with all the metering, generator Circuit breaker remote operators and governor governor controls.

There are 4 Main Switchboards, one in each Engine Room and 2 Emergency Switchboards, one located in each AMR. Each Switchboard has 2 Westinghouse Ships Service Turbine Generators(SSTG's) controlled by it. Each Generator can produce 480volt, 1250kw, 2005amp, 3ph, 60hz power for ships service for a combined max.power output of 10 megawatts....more than enough to supply the needs of a town of roughly 20,000. There was a "hierarchy" regarding the Switchboard watchstanders. ALL were qualified watchstanders but in addition to this the #4 watchstander was also the "Load DIspatcher" and the #1 watchstander was the "Electrical Supervisor". Electrical Supervisor was in overall control, he managed the whole electrical plant and load from his position on #1 Switchboard and all 3 other boards answered to him. The Load Dispatcher was the AFT Supervisor, as we almost always ran "Split Plant" he supervised both #3 & #4 switchboards. the only time we paralleled Fore and Aft plants was in the event of a generator casualty and shutdown. When shifting to either ships power from shore or vise versa you chose which plant(Fore or Aft)would go first, brought the load down to one generator capacity, adjusted voltage to match, adjusted generator speed so the sync scope was moving slow in a clockwise direction, at 5' to 12 you closed the beaker and either gave up the load to shore or took it onto your generator. In the 5.5 years I was on board IOWA we NEVER fully lost the load and "Went Cold, Dark, & Quiet" while at sea...came close once due to cascading casualty. We went dark operationally once, pierside, due to human error in Main Control (bad call by UI EOOW). My worst day on board and on watch......19 April 1989.....