We've previously looked at the process by which the first ironclads developed into the dreadnought, and further into the super-dreadnought with guns larger than 12". The next stage in British dreadnought development was driven by a man who later became one of the 20th century's greatest statesmen. In October 1911, as the Iron Dukes were being ordered, a young, ambitious politician named Winston Churchill became First Lord of the Admiralty.

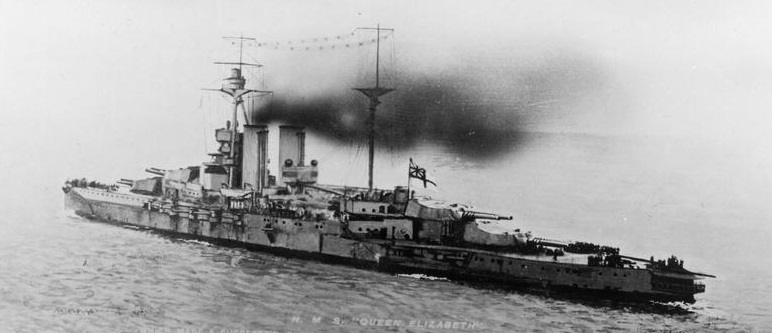

HMS Queen Elizabeth, 1916

Churchill, for all of his great virtues as Prime Minister during the Second World War, had serious vices as First Lord. He was greatly influenced by Jackie Fisher, now retired, who had never quite given up on the battleship/battlecruiser fusion designs first proposed as a direct follow-on to Dreadnought. He proposed1 a ship with full battleship armor and a speed of 28 kts. Fisher also argued for an increase in gun caliber to 15", which Churchill agreed to.

This decision was a tremendous gamble. The 15" gun and turret only existed on paper when the ships were ordered, and any serious problems would have required the four twin 15" turrets to be replaced with twin 13.5" turrets, which would mean the ships were more lightly armed than the Iron Dukes. The first turret wasn't even fired until May 1914, after Queen Elizabeth had been launched. Fortunately, the 15"/42 gun proved to be the best heavy naval gun of the era, arming the last-ever British battleship.

HMS Valiant

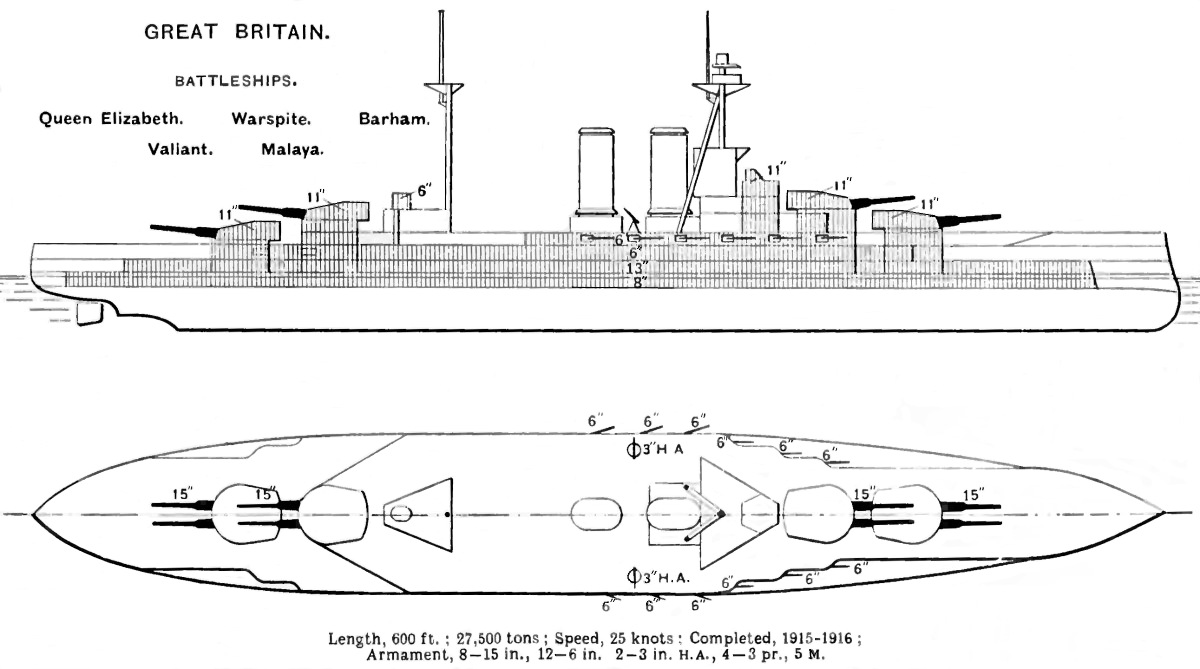

The final ship had a design speed of 25 kts, an armor scheme similar to Iron Duke but with a slightly thicker belt and a torpedo bulkhead running the length of the machinery spaces. The armament was 4 twin 15" turrets, and 16 6" guns, 4 more than the previous class. The resulting design displaced around 33,000 tons, only 10% more than the Iron Dukes.

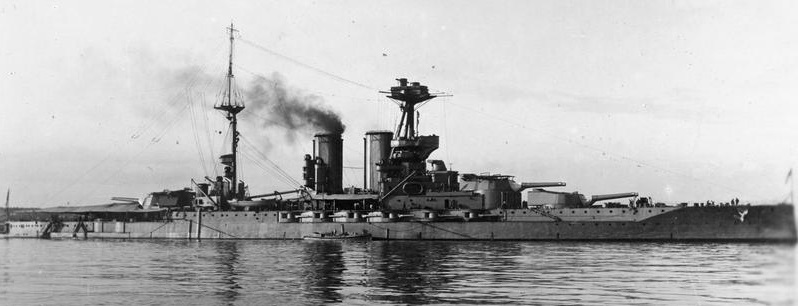

HMS Warspite

The other major innovation in the Queen Elizabeth class was the use of oil fuel. While oil is operationally superior, adopting it required a major shift in British strategy. Before the discovery of the North Sea oil fields in the 60s, Britain had to import all of its oil, while domestic coal was abundant. Churchill negotiated a British investment in the Anglo-Persian Oil Company to guarantee that the ships could be supplied in wartime. While his memoirs, and most later accounts indicate that the ships were intended for oil from the start, the design was in fact prepared for coal power and then converted to oil shortly after it was approved, in mid-1912.2

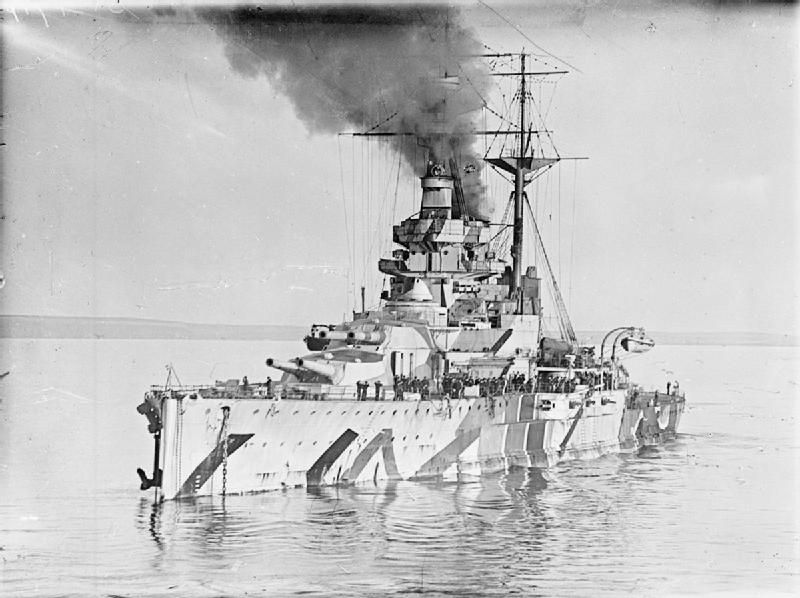

HMS Malaya, with a flying-off platform atop B turret.

Originally, four units of the class were planned for the 1912-1913 budget, but the Federated States of Malaya, a British colony, offered to pay for a fifth unit of the class. The five ships were the first true fast battleships, although they never made their design speed of 25 kts, usually topping out around 24 kts when new. Despite this problem, the Queen Elizabeth was one of the classic battleship designs, with all five vessels serving with distinction in both world wars. Four of the five formed the 5th Battle Squadron at Jutland, where they suffered under some of the most intense fire of the battle, and did a great deal of damage to the High Seas Fleet. Several units were reconstructed in the 1930s, and the entire class went on to face the Germans and Japanese in World War II.

HMS Revenge

The high cost of the Queen Elizabeths, 70% more than the Iron Dukes, forced the British to return to 21-kt battleships in the next program, although the 15" armament remained. Likewise, strategic considerations meant that the traditional mix of coal and oil was used, instead of pure oil. However, the Revenge class3 did exhibit one major design change. Previous classes had had armor on both the middle and main decks, while the Revenges consolidated the armor on the main deck, and fitted a 13" belt up to the main deck instead of tapering it above and below the waterline. This had several advantages. First, the thicker armor was more efficient pound-for-pound than the separate decks of previous classes. Second, protected volume was greatly increased, which increased damaged stability. This allowed metacentric height to be reduced, giving a slower roll and making the ships better gun platforms. The taller belt also meant that the ship could roll more without exposing the bottom edge of the belt.

Diagram of the Revenge class

Ultimately, the Revenge class matched the Queen Elizabeths in numbers, if not in combat success or fame. While under construction, they were converted to burn only oil, probably at Fisher's behest. However, they retained their original boilers, which were smaller and originally intended to burn coal. Despite the delays imposed by WWI, most participated at Jutland, and they served in second-line roles during WWII. Unlike the faster ships, they were not extensively reconstructed.

Ramillies in an interesting dazzle paint scheme

The next program, that of 1914-1915, was planned to be a mix of the two classes, with one repeat Queen Elizabeth and three Revenges, although Churchill had hoped the Canadians would contribute an extra three Queen Elizabeths, much as Malaya, New Zealand, and Australia had bought ships for the RN.4 This plan was disrupted by the outbreak of war, and none were completed to the original design. Two of them, Repulse and Renown, were being built by commercial yards. Jackie Fisher had returned to the Admiralty, and to both avoid contract cancellation penalties and to get more battlecruisers quickly, the ships were completed as battlecruisers. These ships, and the other wartime battlecruisers, will be our topic for next time.

1 Most of the papers related to the design of what became the Queen Elizabeths were destroyed, probably because many senior officials were not entirely happy with the resulting ships when they were first commissioned. This is somewhat ironic given their success in service, but it means that this section is speculative and based on Friedman's British Battleships. ⇑

2 The removal of coal meant that significant space was freed up on the middle deck. It was unsuitable for messing (housing and feeding sailors), but was used for sanitary facilities instead. ⇑

3 Sometimes known as the Royal Sovereign class. I've decided to follow wiki's convention here to prevent confusion with the Royal Sovereign class pre-dreadnoughts. ⇑

4 A bill to do so was introduced in Canada, but failed to pass. ⇑

Comments

I've frequently seen tonnage used as a rough proxy for building cost (at least for the era in question), so a 70% increase in cost for a ship that's only 10% heavier is a bit startling. Although thinking about it a bit, I shouldn't be too surprised at a speed-based design being a lot more expensive per ton, since a ton of precision machinery is harder to make than a ton of armor plating.

The relationship between cost and tonnage is a complicated one. It's typical to assume they're correlated at 1:1, but when tonnage limits get put in place, that goes out the window. During the treaty era, you got stuff like minor fittings (ladders and the like) being made out of aluminum to squeeze more out of the tonnage cap, which also drove cost up dramatically. The same starts going on throughout the design, although this probably wasn't a huge driver on the QEs. One of the big contributors on the QEs cost was the tapered armor belt, which was much more expensive than armor of constant thickness. It was eliminated in the Rs to hold down cost.

(Also, I may have looked at the wrong source for the tonnage increase. I'll double-check that, but it might have been more like 20%.)

One would presume that the cost of developing a new gun and a whole new propulsion system must have driven up the cost the QEs relative to the Iron Dukes, but I have no idea by how much relative to the tapered armor.

I'm not even going to speculate on that offhand. I don't remember who was paying for systems development at this point, as it changed a coupe of times during that era. I know that armament cost was often excluded from figures, but I have no clue if Friedman compensated for that.

I've done a bit more digging into the tonnage rise. 10% is right for full load displacement. Standard is more like 15%. I suspect the gap has to do with the switch from oil to coal, as coal-burning ships usually had extra space they could cram with coal when they needed more endurance. That's not really practical with oil. But I'll stick with 10%, on the grounds of choosing consistent numbers.