WWII was full of startling technical feats. Some of these are well-known, such as the Manhattan Project and the various code-breaking initiatives. Others are more obscure, things like the various guided weapon programs. But one project managed to revolutionize a facet of warfare, literally doubling effectiveness, but has languished in obscurity: the proximity fuze.

Any attempt to shoot down aircraft with unguided weapons runs into a simple problem. The sky is big and airplanes are relatively small. At low altitude, this can be countered by a high rate of fire, but small bullets quickly lose velocity, so another solution is needed for targets at high altitude. The traditional solution is to fit the shells fired by heavier guns with time fuzes, set to go off at the point the shell should be nearest to the target. This raises another problem, though. Now, instead of just trying to get a shell to meet the airplane in three dimensions, you have to match it in four or it will either detonate short of the target or go sailing harmlessly by. Even a perfect match wasn't a guarantee of success, as the time fuzes are not perfect and can only be counted on to detonate within 100 yards of the desired point, a variance significantly greater than the lethal radius of the shell. As a result, the US 5"/38 gun required an average of 654 time fuzed shells for each enemy plane shot down in the Pacific. The question on the lips of every gunnery officer was simple. "Why can't they make a fuze that knows when to go off?"

The answer was a proximity fuze, so called because it was set off by the proximity of the target, and interest in such a device stretched back to before the outbreak of war. There were lots of potential solutions to the problem, ranging from acoustic (microphones set to detect the sound of aircraft engines) to photoelectric (set off by seeing the target using some extremely clever electronics) to magnetic (detecting the metal in the target, much like magnetic mines do). The Germans alone had over 30 proximity fuze programs, covering all of these methods and more. All of them could be made to work in the lab, but miniaturizing them to fit into a weapon, and making them cheap and reliable enough to be useful in combat, was a tall order. Initially, most work focused on bombs and rockets, which didn't have to face the extreme accelerations or high spin speeds of shells, and usually had more space for complicated fuzes.

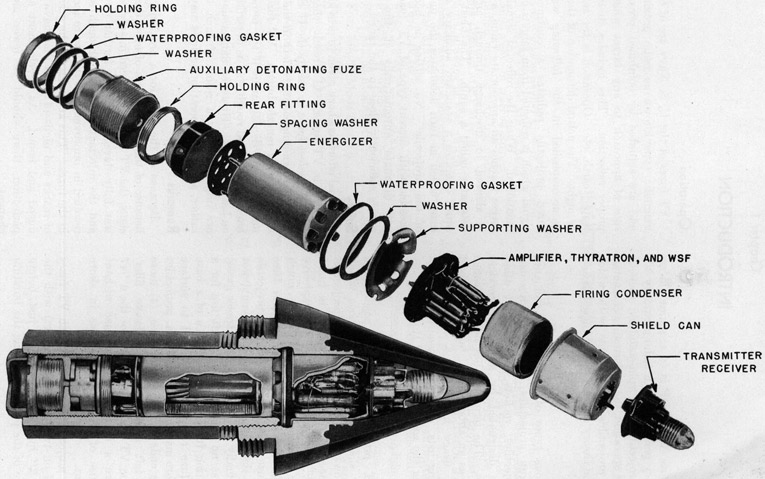

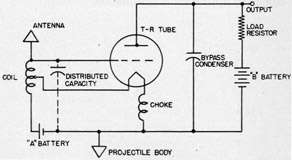

The Receiver-Transmitter Circuit

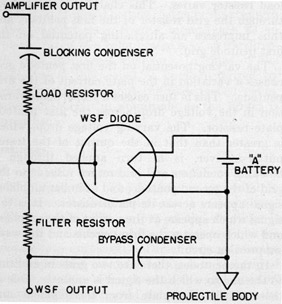

The British had come up with another solution before the outbreak of the war, the use of radio to detect the target. As this was before the invention of transistors, any device would have to be made from vacuum tubes, which meant that initial work, like in so many cases, focused on "unrotated projectiles", AA rockets that the British used extensively in the early years of the war. The basic idea was to use a single tube as an oscillator, producing a radio-frequency signal that was transmitted using the body of the projectile as an antenna. This was reflected by the target, and the signal was picked up by the shell body and fed back into the same circuit that produced the transmitting signal. This seems a curious decision, but the engineers were able to make use of it to greatly simplify the circuit.

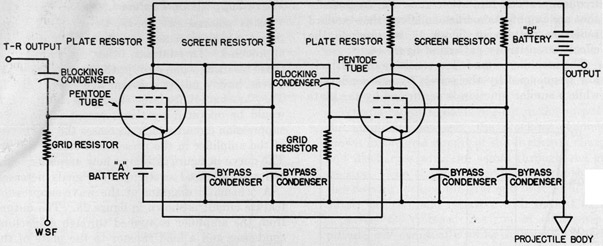

When the projectile was a whole number of wavelengths away from the target, the waves returning from the target were in line with those about to be transmitted, and the voltage in the circuit would be greater than it would normally be. Move it half a wavelength closer, and they would interfere destructively instead, decreasing the voltage. The passage of the shell by the target would thus produce what was essentially a beat frequency,1 which fell into the audio range. This made it easy to filter out and pass on to a two-tube amplifier, which would boost the signal so that it could trip the fourth and last tube, a thyratron, at the right moment, passing a charge into the detonator and setting off the projectile.

The amplifier circuit

All (relatively) simple in concept, but incredibly difficult to put into practice. The British passed the concept to the Americans, who looked at it and decided that they could probably make a version that could actually be fitted into a 5" shell fuze. Using glass vacuum tubes. And so they set to work, initially testing tubes by expedients like dropping them off of buildings, but later moving on to actual firings from a vertical gun. Usually, the falling shell landed softly enough for the internal components to survive,2 and they quickly discovering that it was in fact possible to protect tubes from the shock of gun launch by potting them in wax to keep the glass from breaking. Careful design work was required to make sure that the internal components would also stand the shock of acceleration without breaking or showing undesirable electronic effects, known as "microphonics", and to miniaturize the tubes to the size required, about equivalent to the metal and eraser on the end of a pencil. It weighed about three grams, although during firing, the equivalent weight was about 140 lbs. The excellent book The Deadly Fuze says it best. "Imagine, if you will, a good-size girl standing with all her weight on one stiletto heel bearing on a tiny glass tube."

Mass production of the tubes was also an enormous challenge. 95% of the tubes were built by Sylvania, who employed ten thousand personnel, mostly women, to turn out a million of the tubes every two and a half days, two-thirds the rate of production of the entire prewar American radio industry. During the course of the war, the proximity fuze program as a whole cost approximately a billion dollars in contemporary money, or about $15 billion today. The cost per fuze fell from $732 in 1942 to as low as $18 in 1945, and over 22 million were produced. While the Navy had driven the program and received the first fuzes, three-quarters ultimately went to the Army, which used them both in AA guns and to burst artillery shells shortly before they hit the ground, greatly increasing lethality.

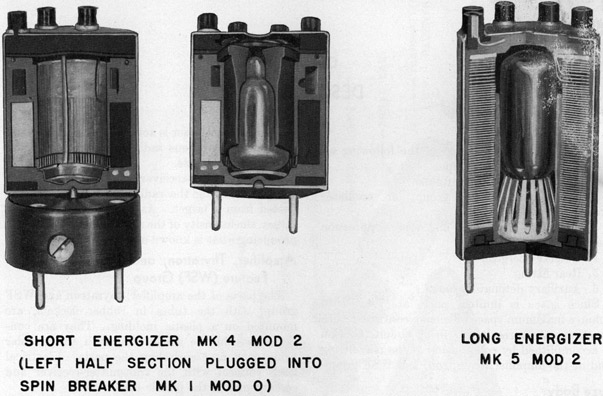

Reserve batteries

Nor was tube development and production the only challenge. The first fuzes used conventional dry cell batteries, which worked well enough, but had a shelf life of six months or so, falling to half that under storage conditions in the South Pacific. New batteries were regularly flown to the war zone, but something better was needed. The solution was a reserve battery, where the liquid electrolyte was stored in a glass ampule which broke when the shell was fired. It would then be forced into the plates of the battery by the shell's spin, giving an extra margin of safety against premature detonation. This worked quite well, although the ampules were built in a factory that had previously produced most of the nation's Christmas lights, which were unavailable for the rest of the war.

Safety was paramount, and a great deal of work went into making sure that the fuze wouldn't operate until a half-second had elapsed after firing. The capacitor that fired the squib wasn't charged until the shell was in flight, and to back this up, early shells used a clockwork time fuze activated by the centrifugal force of the shell's spin. This was too bulky for later, smaller fuzes, and a system that used the spin to force the mercury which had been shorting the squib through a sintered, and thus somewhat porous, metal cup was developed. All components were subject to extensive testing programs, with a target reliability of about 80%, which meant that in a few cases, 4 subcomponents were rejected for every one put into an operational fuze.

Even once the components had been manufactured, there were still many challenges to overcome. The fuze sensitivity had to be fine-tuned to make sure the shell wouldn't go off too soon or refuse to detonate even when close enough to the target. This was done via firing trials over the Potomac River,3 as using aircraft would have been rather difficult. Later, tests on replica airplanes suspended from giant towers were carried out to verify that the burst pattern did indeed work as expected. To further improve performance, actual planes were used, although the projectiles were contact-fuzed and fired through sheets of plywood to make sure they went off where they were supposed to. Because of tests like this, by the end of the war improved fuzes and shells had increased the lethal area of a burst threefold.

The Wave Suppression Circuit

One issue discovered in these kind of tests was that return from waves could trigger a shell fired at low-flying aircraft, even if the shell was a thousand feet up. This was obviously a problem, and a circuit known as the Wave Suppression Feature was added. It reduced the sensitivity of the amplifier circuit to long-duration signals, such as that produced by the ocean's surface, but didn't respond quickly enough to cut off the signal from an actual airplane.4 This was also found to provide superior resistance to jamming, although neither the Germans or the Japanese managed to get a successful jammer for the fuzes into operation.

The first live test of the fuze, known by the codename VT,5 was conducted by the cruiser Cleveland on August 12th, 1942. The first drone, making a simulated torpedo run, was downed with only 10 rounds. Another was sent up, and shot down in a similar interval. A third drone was requested, only for the test team to be told that none was available, as they normally took hundreds or thousands of rounds to bring down. The next day, a drone simulating level bombing met the same fate, and Cleveland was ordered directly to the Pacific to keep the crew from talking. The shells would follow within a matter of months, and their performance will be a subject for next time.

For more information on these fuzes, see this manual.

1 An alternate formulation is that the beat frequency was set up by the doppler-shifted return frequency and the original signal. This is apparently the same thing deep down, but I don't understand circuits well enough to be sure. ⇑

2 In one case, a rash of failures on this test was discovered to be caused by unusually cold weather at the test site freezing the ground. ⇑

3 Getting close to the ground produced the same effect that getting close to a plane did. ⇑

4 Initially, this circuit, which took an extra vacuum tube, was not included in fuzes being built for the Army's artillery, but it was discovered that without it, rain caused an unacceptable increase in premature detonations. ⇑

5 From Variable Time, chosen as a codename which would say what the fuze did without giving away anything about the mechanism. Note that it's referring to the period after the shell is fired. ⇑

Comments

I wonder whether VT fuses also had the benefit in the anti-air role of confirming that the guns were aimed correctly. Since they only go off if the shells are flying near the planes.

It's also interesting to note that these can't be mixed in with tracers, since the trail of ions left by the flame interferes with the electronics.

654 time fuzed shells for each enemy plane shot down in the Pacific

Actually that is much better than I would have guessed.

@Lambert: I read somewhere that they would mix regular timed shells in with the VT shells, so that they'd be able to see puffs of flak wherever they were aiming.

@Lambert

That's going to be a drawback. I can't recall hearing about the mixing of timed shells to confirm aim, but it makes a lot of sense. Timed shells provide spotting capability similar to tracers (which I guess could give the fuzes trouble, although VT-fuzed shells were of sizes that never carried tracers anyway) while a VT-fuzed miss is invisible. I'd guess it's a more recent thing, as modern proximity fuzes can be much smaller.

VT fuses also seem to have lacked somewhat in deterrent effect (for aircraft not hit - obviously aircraft which are shot down are almost 100% deterred) compared to timed fuses. The sight of the sky around them filling up with lethal bursts of smoke tended to distract aircrews, no matter how brave, which often had negative consequences for their aim. VT fuses were more deadly, but less obviously scary.

The manual recommends 50-75% VT for general use, and up to 100% for night action and against divebombing.

@Lambert

Which manual? This sounds like something I need to look at.

The first place I had heard about VT fuses was histories of the Battle of the Bulge, where they were deployed for the first time "over land." There was a huge issue with secrecy delaying deployment, but BotB was considered to be a Massive Threat justifying the use. Also, with air support grounded due to weather, more of "supporting fires" had to be delivered by artillery. The densely-forested Ardennes made VT even more deadly, because the shell's own fragment effects were increased by the fragments generated from the overhead cover shredded by the blast. (Or so it was written).

The other place I saw any mention of the development was the foreword to the edition of the Complete Equilateral that I have. The author worked on development of the VT fuses. Arthur C Clarke wrote the foreword, and mentioned this in an aside, along with how insane the thought of putting vacuum tubes in an artillery shell was at the time.

Re: All the comments above about visual aiming aids (tracers, timed fuze bursts, etc.), the success of the VT shells benefitted greatly from radar controlled gun directors. Navy AA guns were aimed by radar and not a shoot-watch-adjust feedback system.