Battleships faced two great threats. The first and most obvious was from shellfire, and it was dealt with by the armor that was in many ways the signature of the battleship. But armor can only protect against threats from above the water. The other great threat, attack by torpedoes and mines, required different solutions because of the nature of underwater explosions. But solving it was imperative, because it turned out to be the more lethal in the long run.

Torpedo hits on West Virginia and Oklahoma during the attack on Pearl Harbor

Underwater explosions are very different from explosions in air, due to the greater density of water. This allows it to transmit shockwaves more effectively, but more importantly it contains the gasses created by the explosion. Instead of expanding rapidly into the relatively sparse air, they are contained and have to accelerate the water around them outward. Even when the pressure inside the bubble is equal to the pressure outside, the inertia of the water carries it outward. By the time the bubble stops expanding, the inside is rarefied, and the bubble begins to collapse, compressing the gasses. Eventually, they are compressed by the inertia of the inrushing water, and the cycle repeats.

Unfortunately, this process is much slower to disperse energy than an explosion in air, which means that conventional armor is not particularly effective.1 Designers realized that the most effective way to protect against an underwater explosion was to attempt to disperse and absorb the energy of the blast, rather than trying to keep it out entirely. Although it took some of them surprisingly long to realize it, they also faced the danger of fragments from the ship's structure, driven by the blast, piercing any barriers they erected. Later, other means of attack would complicate TDS2 design even more.

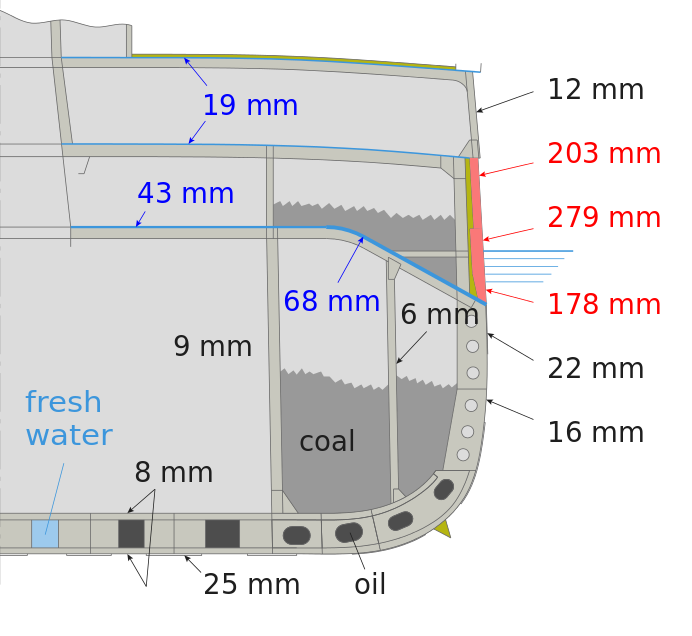

Cross-section of HMS Dreadnought, coal-only protection

Pre-dreadnoughts, and even many dreadnoughts, relied entirely on their coal bunkers for torpedo protection, sometimes adding armor patches over the magazines.3 Coal was actually quite useful in this role, as it absorbed a great deal of energy when pulverized by the explosion and was quite effective at catching fragments. The fact that a typical bunker was about 60% full of coal by volume to start with meant that only a limited amount of water could flood into the ship from a hit, limiting how much off-center weight was added from a hit.

HMS Hotspur with torpedo nets deployed

Despite these advantages, coal had serious drawbacks as a protective material. Most systems required that the torpedo bulkhead be pierced by scuttles to give access to the coal,4 and these were often either found to be non-watertight or left open at critical moments. Even worse, the scuttles often sprang open under the force of an explosion. Coal dust, whether generated in normal operations or by coal pulverized by a blast, is highly flammable and even explosive. And perhaps worst of all, an empty coal bunker provides substantially worse protection, but if coal was reserved for protective use, the ship's range fell dramatically.

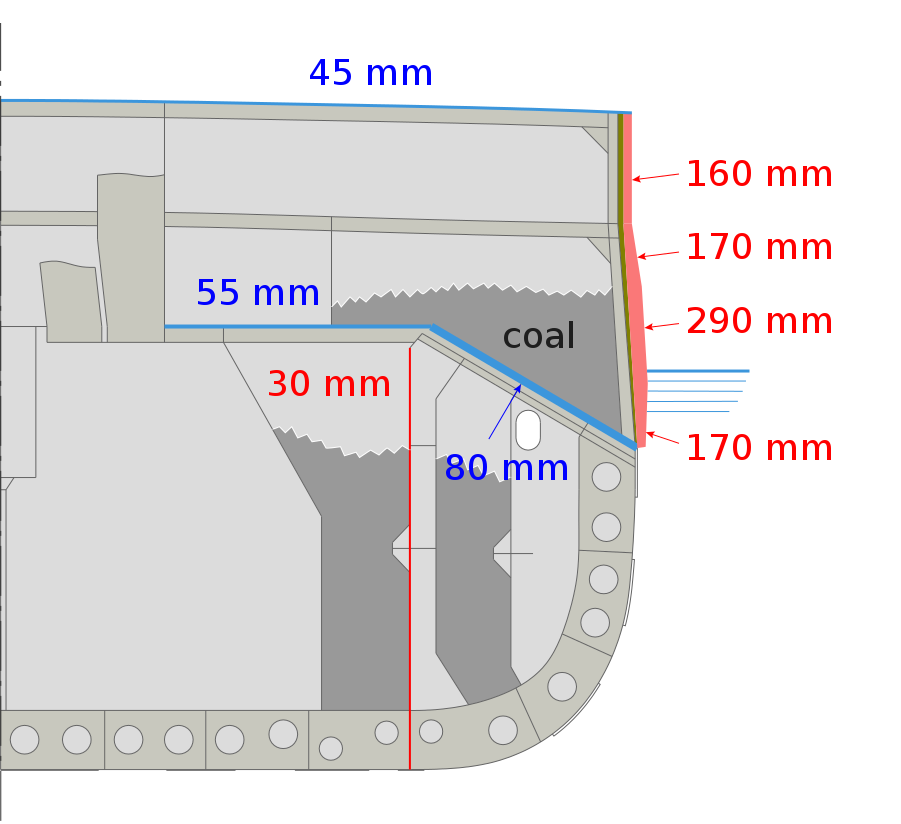

Cross-section of SMS Westfalen, with armored bulkhead

In an attempt to improve on this protection, some ships were fitted with an armored bulkhead behind (inboard of) the coal bunkers, usually 1-3".5 The Germans took this the furthest at the time, expending considerable funds on full-scale testing, and devoting a lot of space to the TDS. They, among others, discovered that the effectiveness of coal was enhanced by placing a void outboard of the coal bunker, allowing the gasses to expand and dissipate before they began to destroy the bunker.

These principles would prove vital throughout the reign of the battleship. Unlike armor penetration, no reliable equations to predict TDS performance were ever developed. Even small-scale testing proved unreliable, as the effects of explosions did not scale smoothly. In many cases, a ship's TDS was designed based on past experiments and scale tests, and either never tested in full scale or only tested after the ship had already been built. In several cases, this lead to embarrassing flaws which weakened the TDS far below its design limits,6 although these were most prominent in the treaty battleships, and will be covered next time.

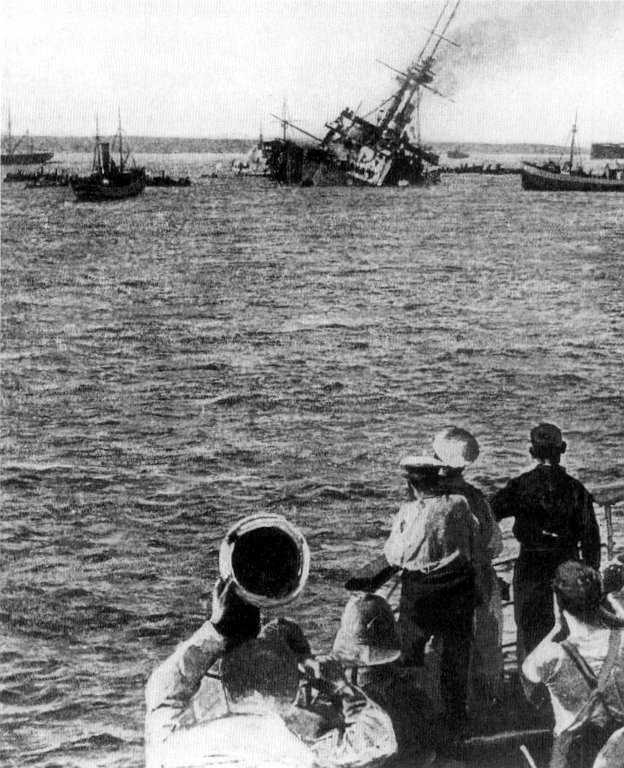

Pre-dreadnought HMS Majestic sinking after being torpedoed

When oil fuel began to replace coal, one of the major reasons given for retaining coal was torpedo protection. Oil was seen as a fire hazard, and the Royal Navy refused to store oil in the sides of a ship, keeping it only in the double bottom. However, as experiments were carried out, it became obvious that oil was probably less hazardous than coal and would also allow more effective torpedo defenses. A gas bubble impacting a liquid-filled layer would lose energy and spread out across a much greater area, increasing the effectiveness of any bulkhead behind it. This bulkhead had to be very elastic, bending and tearing instead of shattering into smaller pieces that could become projectiles in their own right. When fragments were formed, the liquid layers were very effective at slowing them down. There was usually a second void behind the liquid layer, to give the aft bulkhead room to deform without damaging anything behind it. The last bulkhead, known as the holding bulkhead, separated the TDS from the vitals of the ship.

Another major advantage of oil was that the properties which made it effective in a TDS were shared by water. Coal-fueled ships had to choose between steaming endurance and torpedo protection, but a vessel that burned oil could simply fill the tanks with water as they were emptied, and continue on its way. This wasn't entirely without drawbacks, as the water would react with any residual oil to form a thick sludge. This was difficult to remove in the cramped confines of a ship's voids, and the pipework that was required to support this offered potential flooding paths. For this reason, some ships were built with protective systems that used only water, or no liquids at all.

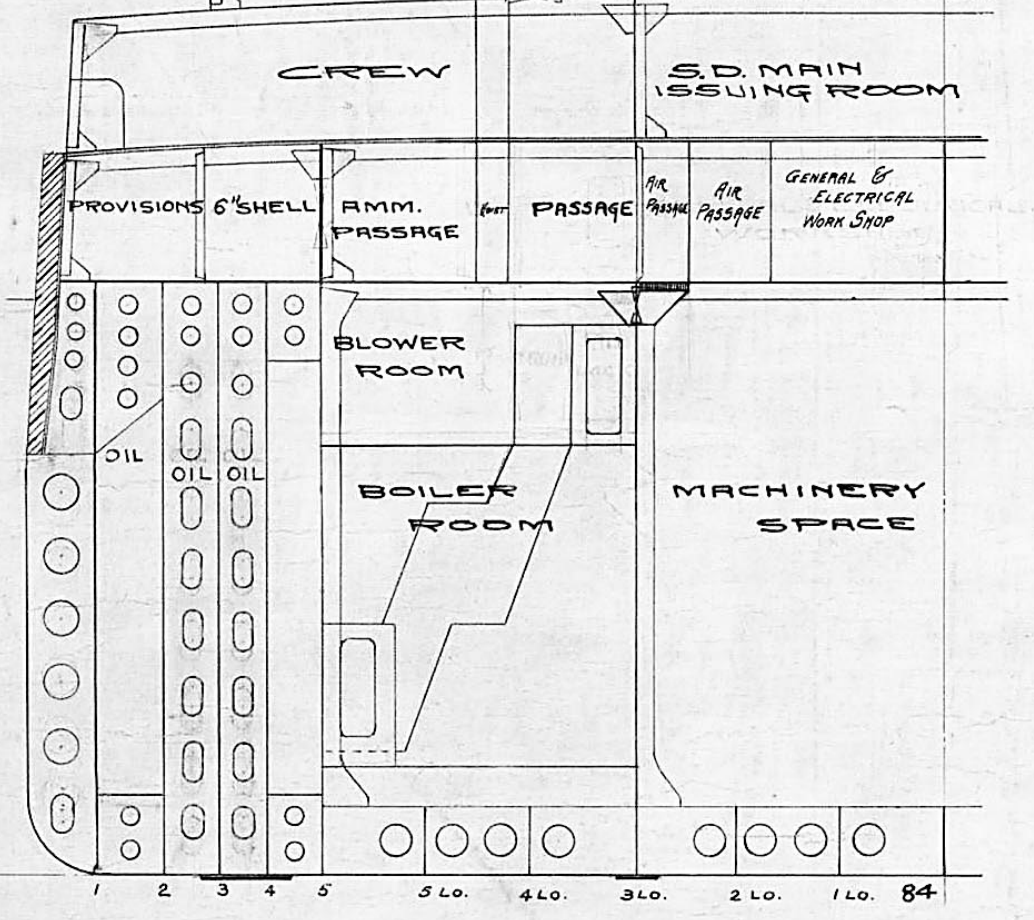

Cross-section of US turboelectric TDS, from South Dakota (BB-49) class

Despite these advances, the most important single factor in the effectiveness of a TDS remained its depth. The further the holding bulkhead was from the explosion, the less concentrated the energy was at the bulkhead, and the greater the chance that the vitals would not be flooded. But this required a lot of volume, which placed a squeeze on space available for propulsion. One of the best of these systems, even when compared to the WWII battleships, was the TDS for the US turboelectric battleships, with a single void outboard, three liquid layers, and a second void before the holding bulkhead. The system was 17' deep, nearly twice the depth of the TDS in earlier US battleships, an increase allowed by the more compact turboelectric plant.

When tested in combat, these systems held up well. During the attack on Pearl Harbor, West Virginia was hit by a total of seven torpedoes. The TDS took three of them without failing, although the ship was sunk by other torpedoes which passed above the TDS and hit the belt7 and later, as the ship sank, the armored deck. California's TDS also resisted the torpedoes which hit her, although the fact that she was opened up for inspection meant she sank anyway.

Torpedo damage to California after Pearl Harbor

During and after WWI, more advances were made in protecting battleships against torpedoes. We'll discuss them in more detail next time, along with new threats which appeared in the interwar years to menace the battleship.

1 If this doesn't make sense, think of it like this. Generally, air is much easier to push out of the way than steel, so most of the blast isn't going to go into the armor. There tends to be a lot of water around/over an underwater explosion which an explosion will need to push out of the way, so the steel plate might become the path of least resistance. ⇑

2 Torpedo Defense System, sometimes also called Side Protection System (SPS). ⇑

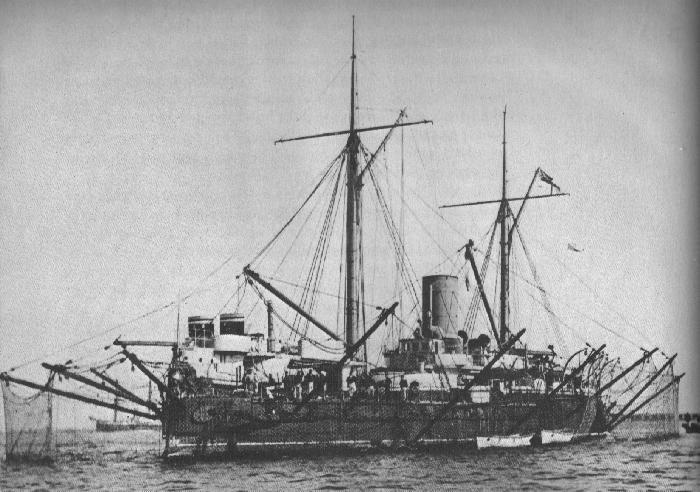

3 Another common means of torpedo protection in the early days was the torpedo net, a metal net deployed from booms on the side of the ship. These booms can often be seen in pictures of battleships before WWI. The nets were only useful when the ship was stationary, but in the early years of the torpedo, that was considered to be a serious threat. Nets fell out of favor around the start of WWI for a couple of reasons. Torpedoes were fitted with net-cutters, the threat of attack on a stationary fleet faded and there was increasing concern that the nets would be damaged in battle and tangle the propellers. ⇑

4 In a few cases, dedicated bunkers were used for direct supply to the boilers, and coal from the bunkers outboard of the torpedo bulkhead was retrieved from above, allowing an unpierced bulkhead. ⇑

5 Norman Friedman, in Battleship Design and Development, suggests that the choice of this bulkhead for the British was determined by how the balance between torpedoes and long-range gunnery looked in a given year. If the torpedo seemed ascendant, the bulkhead was used. If gunnery seemed to have the upper hand, the weight was used for weapons and armor instead. I'm not sure if these bulkheads were pierced by scuttles or not. ⇑

6 A TDS was typically designed to resist a given weight of charge, so many pounds of TNT or a similar explosive. This value was determined by the space available and the torpedoes of likely adversaries. ⇑

7 The ship had gained considerable weight since completion, which meant that she was lower in the water, and the torpedoes were able to pass over the TDS. ⇑

Comments

What were the torpedoes themselves like at this point? Range, speed, yield etc?

At some point, I intend to write a series on the history of the torpedo (I have a book on the subject, of course), but here's the really quick sketch. For more details, see the detailed catalog of torpedoes at NavWeps. Around 1900, a typical torpedo was capable of reaching 1000 yds at around 27 kts, and had a warhead of 100-200 lbs of wet guncotton. By 1905, range had quadrupled, but speed remained about the same. Alternatively, most torpedoes of this time could be set for higher speed and shorter range. By 1910, TNT had begun to be used in warheads, and many of the warheads were more like 320 lbs. Range had doubled again, and speed was creeping up slightly. The best torpedoes of WWI were capable of something like 10,000 yards at ~30 kts (and possibly more at lower speed), and had 500 lb warheads. But there was a lot of variation. Surface-ship torpedoes were usually significantly faster and longer-ranged than submarine and aerial weapons.

The speed's particularly important, since one of the main counters to torpedo attacks (at least in WW1) was to turn away from the torpedo. This helped partly by presenting a smaller target to the torpedo (homing and wire-guided torpedoes weren't developed until well into WW2), but mostly by keeping the range open until the torpedo ran out of fuel: a 30-knot torpedo in a stern chase with a 24-knot fast battleship is only closing at 6 knots. In the ~10 minutes the torpedo can run before exhausting its fuel (based on a 10,000 yard range), it will only close a relative distance of about 2000 yards. Because of this, the main benefit of a torpedo attack on an alert fleet with steam raised is to force it to turn away (like Sheer did at Jutland, sending in his destroyers with torpedoes to force Jellicoe to turn away long enough for Sheer to break contact), not to actually sink ships.

I imagine that's part of the reason for the concern Bean mentioned about torpedo attacks against stationary ships: if a reasonably fast warship can defend itself by turning away from torpedoes in most circumstances, the main threat is a surprise raid against a fleet in an unfortified harbor or a fleet anchored off an enemy shore to conduct bombardments or support a close blockade.

Battleships got a lot faster by the WW2 era (the three I just looked up were 28 knots (Duke of York), 30 knots (Bismarck), and 33 knots (Iowa)), but torpedoes look like they got even faster. Bean's link shows the British and Americans at least as having torpedo models with top speeds around 45 knots, for a 12-17 knot speed advantage.

@Eric

Good points, although in action it was somewhat more complicated. Ships didn't always run around at full speed, and could be somewhat slow to accelerate. For that matter, it wasn't always apparent when torpedoes were fired, as at Guadalcanal. But besides cutting down effective range, turning away also meant that you had a lot more time to maneuver to dodge as the torpedo closed.

True, especially in a WW2 context, in night actions, or in smaller engagements. I was mainly thinking of WW1-era major fleet actions, where if several dozen enemy destroyers were running at full speed towards your line of battle, it's pretty obvious what they have in mind.

I'd wondered about that. It struck me as a significant consideration when trying to get away from an unguided torpedo, but Massie made it sound like running out the range was the main idea. Running directly away from the torpedo takes the most off the torpedo's effective range, but moving obliquely to the torpedo's course gives you more cross-range motion to generate a miss by sidestepping the torpedo's course.

There are three main reasons to turn away from an incoming torpedo. First, as you pointed out, it reduces the effective range of the torpedo a great deal, and you can hope to just run them out of speed. Second, it greatly reduces the size of the target. For Iowa, you're looking at a target length of 860' beam-on, and 108' from ahead or astern, essentially an eightfold change. The Iowas were unusually slender, but it's probably about a factor of six for a typical battleship. Third, it makes it easier to dodge torpedoes as they approach. Let's say that as the torpedoes finally catch you aboard Iowa, they're spaced every 400'. You have a slightly better than 1-in-4 chance of having one actually on a collision course, and I wouldn't want to let one get too close alongside in case it gets sucked in. So I order some rudder and essentially move aside. After all, the closure rate of a 45 kt torpedo is only 400 yds a minute, less if the torpedo is slower or is slowing at the end of its run. Obviously, two and three don't really work if the torpedoes are dense enough, but they apply a lot of the time.

Also worth noting that until WWII, torpedo tracks could be fairly easily spotted in daylight - maybe not when they were launched from 10,000 yards, but almost certainly as they got close. Propulsion was by a compressed-air engine in 1900, and some sort of internal combustion engine thereafter, but in any event the exhaust turned into an obvious bubble stream at the surface. Sinking a ship with a torpedo (singular; it almost never took more than one prior to the development of the TDS) usually required either a night attack or an attack at point-blank range where the target would not have time to evade. Otherwise, as Eric says, you're just forcing the enemy to maneuver.

By the start of WWII, the Germans had developed electric torpedoes with roughly the performance of the WWI-era combustion engine torpedoes but no wake, while the Japanese had developed oxygen torpedoes with no wake and superlative performance but impressive pyrotechnic properties if your engineers and technicians didn't know exactly what they were doing. By the end of WWII, pretty much everyone had high-performance wakeless torpedoes.

That’s a really good point that I subconsciously assumed everyone knew, and didn’t think to call out.

You are, of course, thinking of the pre-dreadnoughts that died in such numbers to fairly simple underwater damage. The big difference there is the presence of a longitudinal bulkhead (in the center of the ship, usually splitting the engine rooms), which meant that the effects of flooding were compounded with a very large list. Often a list big enough to bring a casemate or some other flooding path beneath the waterline, and that’s the end of that ship. Designers had figured out this problem some years before, but there were lots of ships which still had them at the time. Lots of WWII cruisers, approximately the size of pre-dreadnoughts, survived one or more torpedo hits. The only classes that suffered really badly were a few where the British had used longitudinal bulkheads. Even a fair number of destroyers limped back in after having taken torpedoes.

(All of this is planned for a future column.)

I assume your meaning here is more like "flexibly positioned"? So while being heavier overall, a turbo plant could be laid out to fit within a TDS without compromising it?

I'd love to see some machinery layout diagrams for different eras of ships. it's pretty neglected in a lot of books.

Heavier and more compact aren't mutually exclusive. Particularly when you're dealing with long shafts, which take up a bunch of space. The best head-to-head on this is going to be the Idaho and Colorado plans from HNSA. Not a lot of details, but a decent overview.